Core Advantages

Three Key Characteristics of Sintered Filter Elements

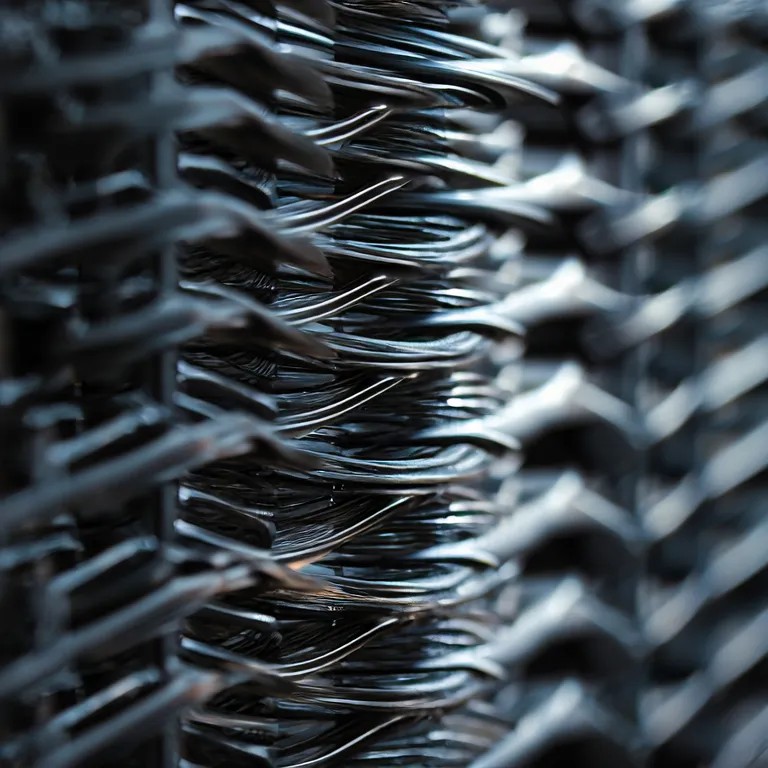

High-Efficiency Filtration: Captures particles as small as 5 microns, with pore structure design ensuring over 95% contaminant removal rate

Exceptional Durability: Metal sintering process delivers outstanding wear resistance and damage tolerance

Multi-Scenario Adaptability: Serves diverse industrial needs from chemical production to food processing

Working Principle

Fluid Inlet: The medium to be processed enters the interior of the filter element.

Multi-layer Filtration: Gradient filtration is achieved through precision sintered mesh.

Impurity Retention: Particles are captured layer by layer.

Clean Output: The purified fluid meets usage standards.

Frequently Asked Questions

Q: What materials are sintered filter elements made of?

A: They are primarily manufactured from metals such as stainless steel and bronze through a specialized sintering process, delivering exceptional mechanical strength and corrosion resistance.

Q: What is the recommended replacement cycle?

A: This depends on actual operating conditions and contaminant load. We recommend establishing a regular inspection schedule.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.