Hydrogen energy, as the core of clean energy solutions, has brought hydrogen fuel cell technology into the spotlight. However, effectively managing gas diffusion remains a critical challenge. High-precision sintered filter elements offer a breakthrough solution by precisely regulating gas flow within fuel cells, thereby enhancing efficiency. This article delves into the application of custom-pore-size sintered filter elements and their role in the hydrogen energy sector, analyzing how material selection and design influence performance. Whether you are an industrial application specialist or an explorer in the renewable energy field, mastering the details of nickel sintered filter elements will empower you to achieve optimal performance.

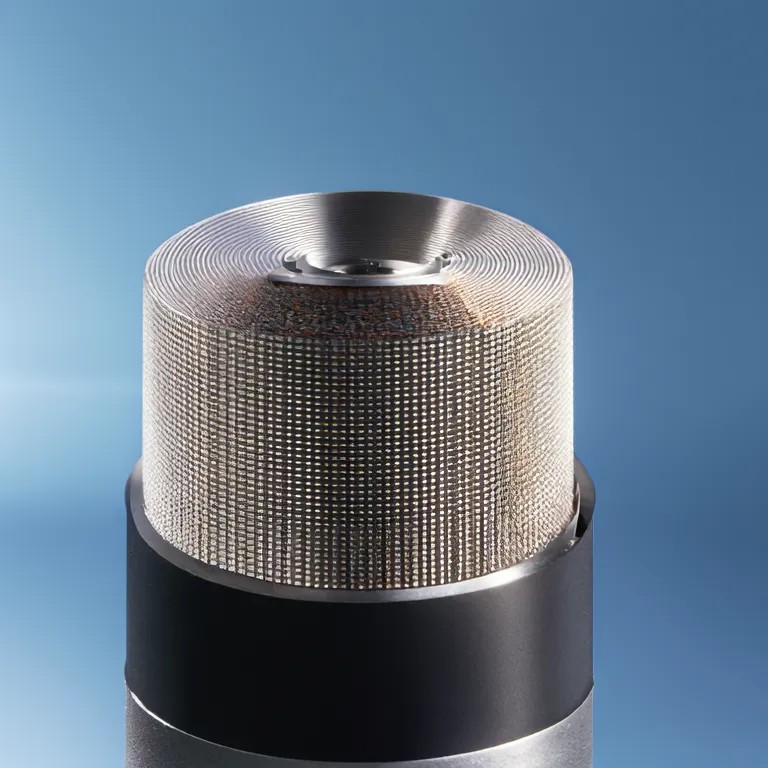

Nickel sintered filter cores achieve precise gas diffusion control through customizable pore sizes, serving as critical components for efficient hydrogen fuel cell operation and significantly enhancing gas flow efficiency.

Three Key Advantages of Nickel Sintered Filter Cores

High Performance: Optimized gas diffusion pathways substantially boost overall fuel cell efficiency

Customizable Pore Sizes: Adapt to diverse hydrogen application requirements for precise gas regulation

Exceptional Durability: Nickel sintered material withstands extreme environments, suitable for industrial-grade applications

Case Data Supplement

Recent studies indicate that nickel sintered filter cores increase hydrogen flow velocity by 20% compared to traditional solutions, which is crucial for achieving higher fuel cell power output.

Working Principle Explained

Hydrogen enters the nickel sintered filter core structure

Passes through a precisely engineered custom pore network

Completes an optimized gas diffusion process

Directionally delivered to the fuel cell reaction zone

Conclusion

Nickel sintered filter elements play an irreplaceable role in hydrogen energy applications, where their pore-customization technology directly determines gas diffusion efficiency. This solution, balancing high performance and reliability, establishes a new paradigm for fuel cell technology advancement. As demand for sustainable development grows, high-precision nickel sintered filter elements will become core components in clean energy systems.

Frequently Asked Questions

Q: What is a nickel sintered filter core?

A: A filtration element formed by sintering nickel powder, specifically engineered to regulate gas flow within hydrogen fuel cells.

Q: How does customized pore size enhance performance?

A: By precisely controlling gas diffusion pathways, enabling more efficient fuel cell reactions.

Q: What is its weather resistance?

A: Nickel sintered material exhibits exceptional high-temperature stability, suitable for demanding industrial environments.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.